Ouroboros

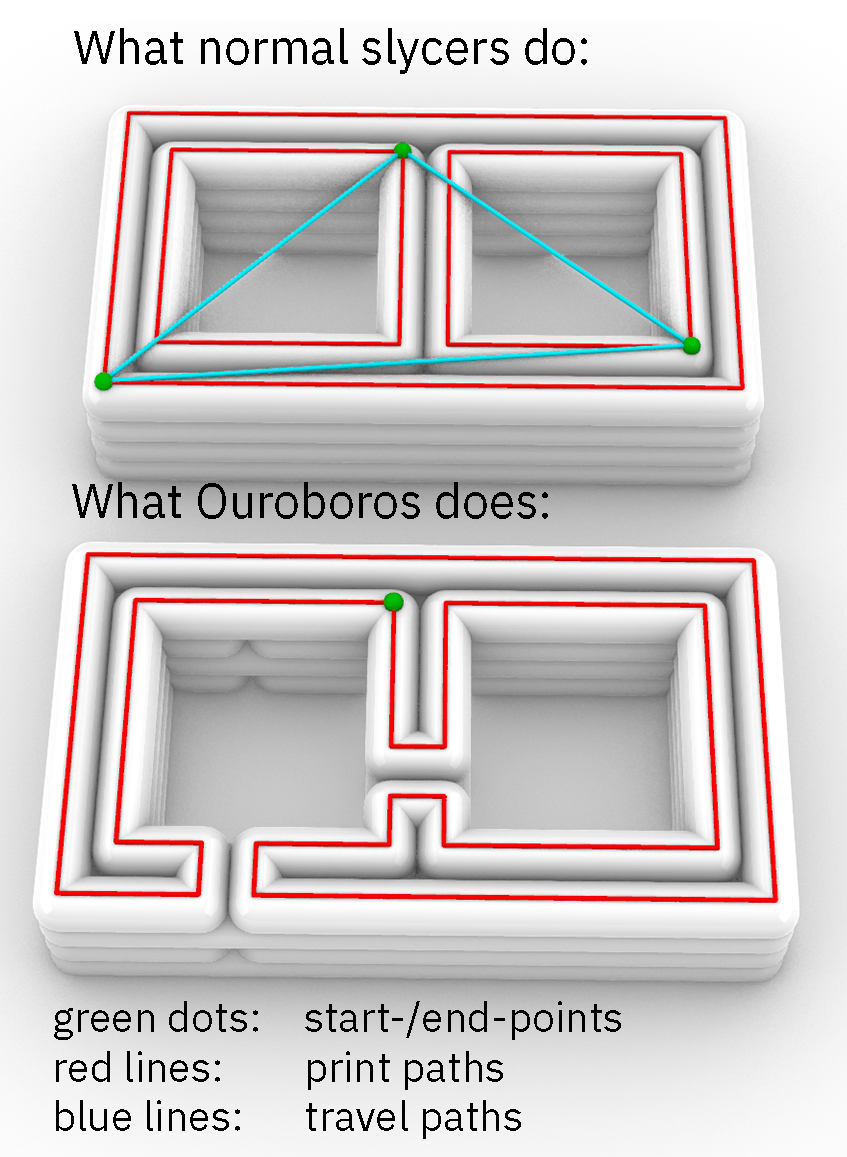

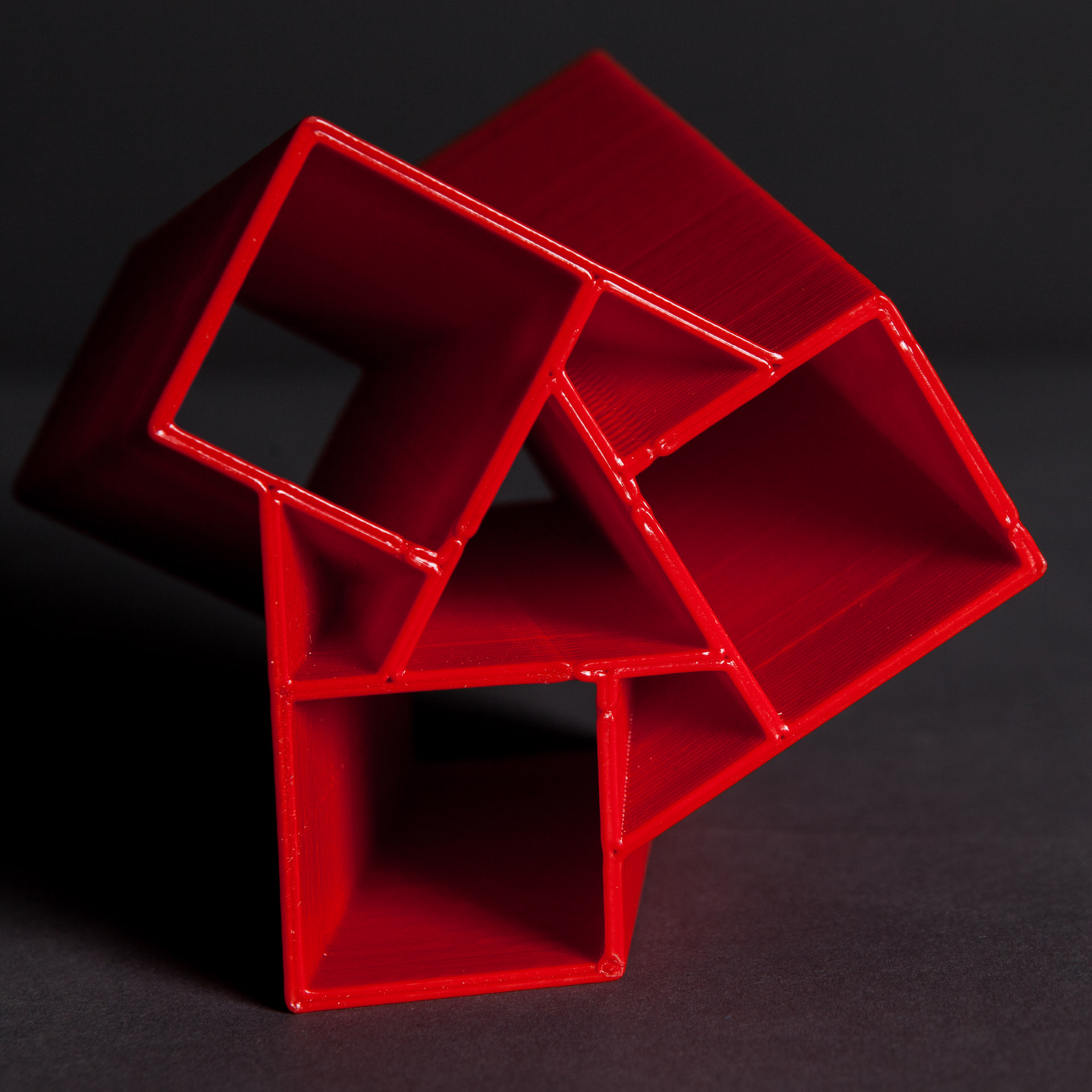

"Ouroboros" is a digital tool for developing products that are 3D printed with large nozzles. In order to avoid the messy surfaces that result from travel movements, Ouroboros is used to connect all the print paths into one large path. Thus, the whole print can be done in one go. This results in 5 times shorter printing times and a beautiful, uniform surface with a special texture and feel. This makes the 3-D printer a practical tool for small-batch production. A first product is the Garberobe.

The fact that decentralized production has social relevance was demonstrated at the beginning of 2020. At that time, I was able to donate over 500 Faceshields because of my speed advantage.

Ouroboros is implemented in Grasshopper, a visual programming interface for the CAD program Rhino. So the entire workflow from design to print code is all possible directly from within Rhino.

Of course, this has some major limitations. All curves must be closed and touch each other in at least one place. But within those constraints, there's a lot of room for creative solutions and functional aesthetics.

If you want to know more about Ouroboros, take a look at my diploma thesis.

You can downloade Ouroboros Here.